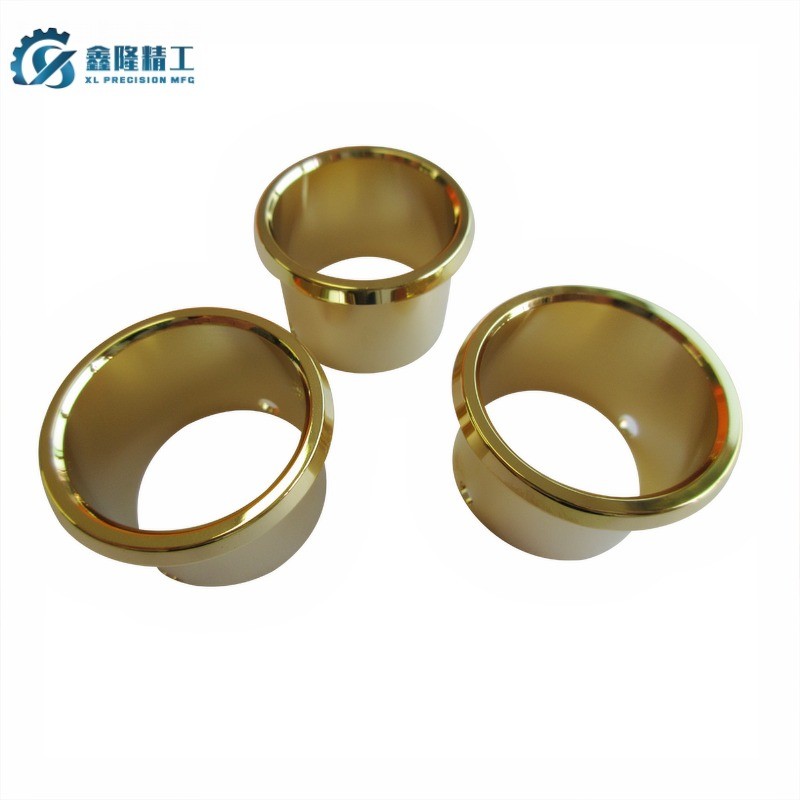

Precision Brass CNC Machining Parts for High-end Audio

- Product Item : brassparts05

- Category: CNC Turning

- Type:CNC Turning

- Material: brass

- Tolerance: /-0.05mm

- Surface Treatment:Polishing,PVD 18K

Precision Brass CNC Machining Parts for High-end Audio

Custom CNC Brass Machining Power Cord Front Ring For High-end Radio Cable Collection

Product Name:Cable Collection Power Cord Front Ring

Material:Brass

Type:CNC Milling and Turning

Tolerance: +/-0.05mm

Surface Treatment:Polishing,Laser laser engraving,Vacuum plating 18K

We have made this part for many years,it is a set of high-end audio cable connector parts,exported to Europe and America.

Materials including brass, aluminum alloy and POM,the surface treatment is very strict.Brass parts need mirror polishing,

and then laser engraving,finally vacuum plating, 18K real gold plating.The parts look very beautiful, very high-end.

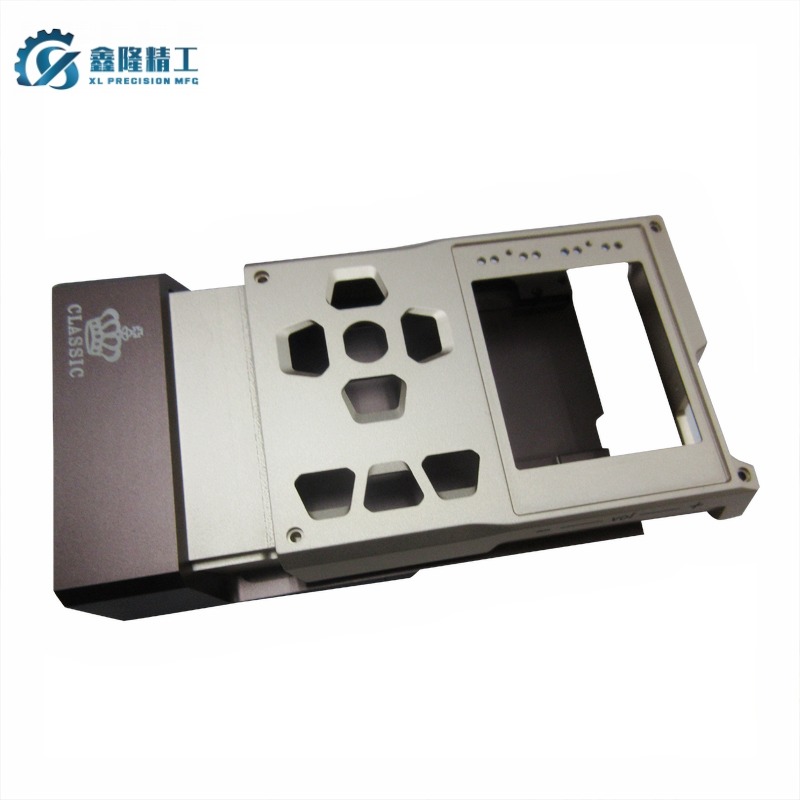

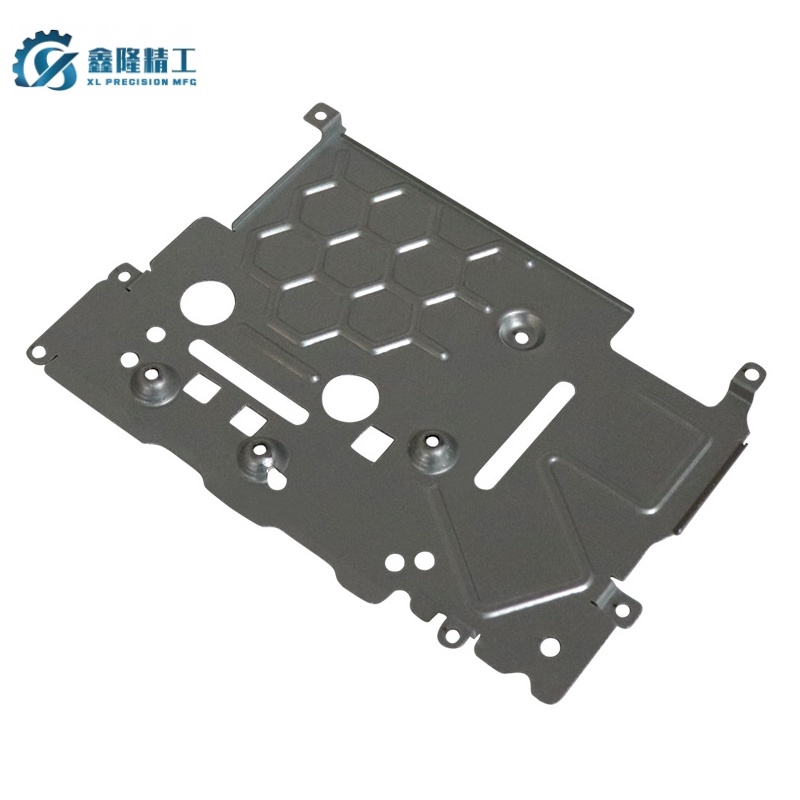

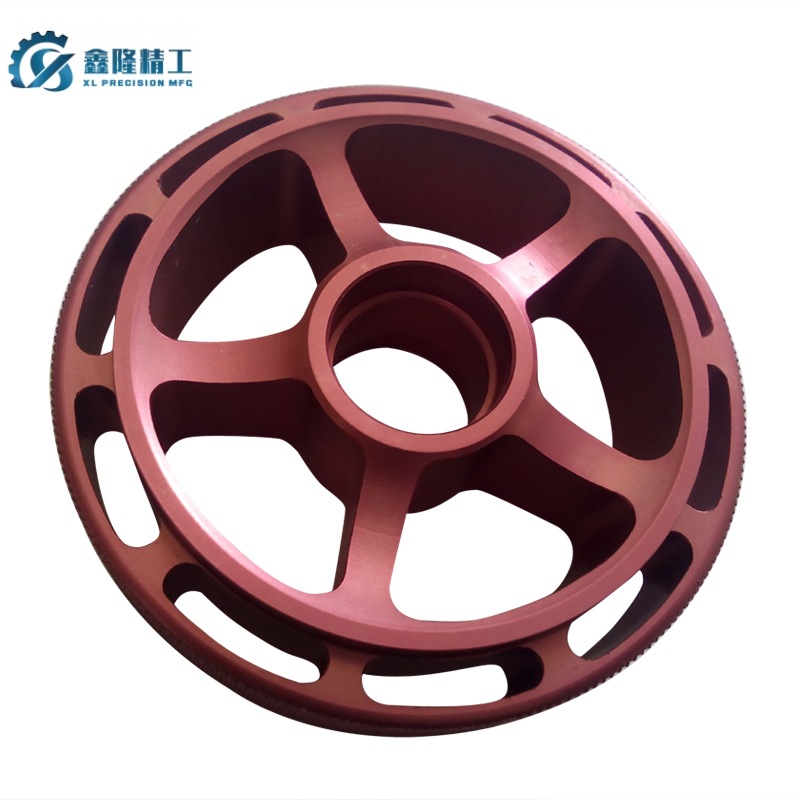

We specialize in CNC processing of complex parts and can handle very complicated surface treatments,such as Screen

printing, silver plating, chromate, hard oxidation,welcome to consult.

Why Choose Us

1. High skilled and well-trained working team under good management environment;

2. Quick response and support for any inquiries;

3. Over 10 years professional manufacture experience to ensure high quality of your products;

4. Large and strong production capacity to meet your demand;

5. High Quality standard and hygienic environment;

6. We have very strict quality control process:

a. In coming Quality control (IQC) – All incoming raw material are checked before used.

b. In process quality control (IPQC) – Perform inspections during the manufacturing process.

c. Final quality control (FQC) – All finished goods are inspected according to our quality standard for each products.

d. Outgoing Quality Control (OQC) – Our QC team will 100% full inspection before it goes out for shipment.

7. Good after sales services;

LATEST NEWS

Contact

CONTACT USName: Linda Wang

Mobile:+86-13923762587

Tel:86-(755)-82596641

Email:linda-cnc@xl-mfg.com

Add:Liancheng Industrial Park,No.16 Shangliao Industrial Road,Shajing Baoan District,Shenzhen City,Guangdong, China